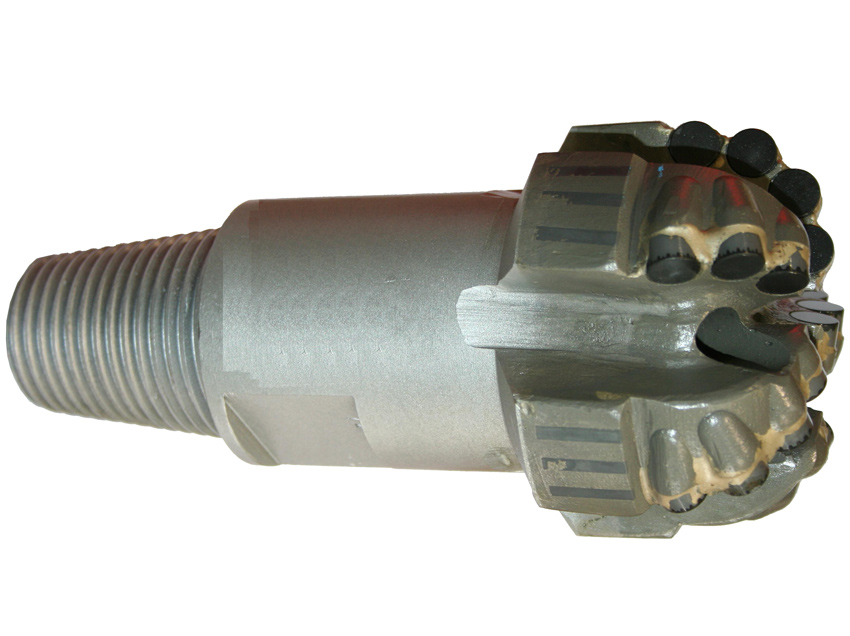

PCD tools originate from the Oil & Gas Industry.

They are perfectly adapted to other drilling activities such as : water well, geothermal, civil engineering, geotechnical engineering, quarries…

The main body is made of tungsten carbide or steel. The PCD bit, for certain drilling conditions, and geological formations, will have longer lifetime than other bits such ad Tricones, Wing-Bits… ad well as a higher rate of penetration with skilled drilling crews, thereby giving you a lower cost per meter.

The body

Our tools are moulded specifically according to the required designs to fit the different number of blades and cutters adapted to the formations and drilling conditions. The cutters are then brazed on to the body.

The cutters

The PCD cutters are of the highest importance in this kind of product and consist of a base in tungsten carbide and a cutting surface in polycrystalline diamond. The PCD cutter presents two main advantages; the diamonds for hardness and abrasion resistance and the carbide for shock resistance

The diamond element is a sintering of crystal diamond at temperatures of around 1400°C and pressures of 60 kbar.